Advanced Oxidation Processes

Targeted

Destruction

of Refractory

Contaminants

with Precision

Oxidation

Technology Overview

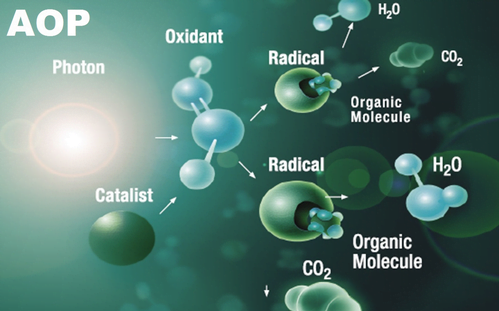

As industrial effluent grows increasingly complex, conventional treatment methods often fall short in removing micro-pollutants, pharmaceuticals and non-biodegradable organics. This is where Advanced Oxidation Processes (AOPs) play a vital role. Engineered to break down the toughest contaminants at a molecular level, AOPs are among the most effective advanced water treatment technologies available today.

Using powerful oxidants such as hydroxyl radicals, AOPs disrupt chemical bonds in persistent organic compounds, making them biodegradable or completely mineralized. Whether applied as a standalone solution or integrated into a larger system, AOPs enhance removal efficiencies, ensure regulatory compliance and enable sustainable reuse in high-risk sectors.

How it Works?

Core AOP Variants Include:

- UV / H₂O₂: Ideal for degrading pharmaceuticals, pesticides and dyes

- Ozone-based AOPs: Suitable for removing taste, odor and emerging contaminants

- Fenton and Photo-fenton Reactions: Highly effective in treating leachates and chemical wastewater

- Catalytic AOPs: Designed for continuous industrial operations with metal-based catalysts

- O₃ / UV / H₂O₂ Hybrid Systems: Deliver the highest oxidation potential for extreme effluent streams

Technology Benefits

- Effective on Non-biodegradable Pollutants: Removes COD, TOC, phenols, endocrine disruptors and APIs

- Minimal Sludge Generation: Reduces downstream sludge handling and disposal

- Compact Footprint: Ideal for integration into existing advanced wastewater treatment technologies and containerized systems

- Enhances Downstream Efficiency: Improves biological treatment effectiveness when used as pre-treatment

- SCADA Integration: Enabled for real-time ORP control, flow modulation and safety shutoffs

Application Areas

- Pharmaceutical and API Manufacturing

- Landfill Leachate and Hazardous Wastewater

- Chemical and Fertilizer Plants

- Textile Dyeing and Finishing

- Municipal Wastewater Tertiary Treatment

- Micro-pollutant Removal in Advanced Water Reuse Facilities

Why Choose WOG Technologies Limited?

As an advanced water technology company, WOG delivers AOP systems as part of integrated, performance-guaranteed packages. Our engineering teams customize the oxidation method based on influent quality, energy budget and target contaminants.

Expertise in advanced treatment technologies for wastewater with proven field results

Modular and scalable AOP systems for plug-and-play deployment

Integrated control through SCADA for safety, efficiency and optimization

Full lifecycle support: Design, supply, testing, commissioning, training and O&M

Trusted by leading clients in high-stake industries across the globe

Upgrade Your Treatment Strategy with Advanced Oxidation

Talk to WOG Technologies Limited about deploying AOPs as part of your advanced water technology roadmap. We engineer customized oxidation platforms that deliver measurable impact on quality, compliance and sustainability.

FAQs

Unlike chlorine or ozone alone, AOPs generate hydroxyl radicals that react non-selectively and aggressively with complex organics, ensuring deeper and faster oxidation with minimal byproducts.

Yes. AOPs are often at the polishing stage in ZLD systems, where they ensure final COD / BOD reduction and remove residual refractory compounds prior to evaporation or crystallization.

AOPs are ideal for removing persistent organics such as pharmaceuticals, pesticides, colorants, surfactants and endocrine disruptors that cannot be effectively treated by biological systems.

Yes. Our AOP units are modular and can be designed for both small-scale applications and large continuous flows with capacities exceeding several MLDs.

AOPs can be inserted before or after biological stages or as a polishing unit. WOG ensures seamless integration with existing automation and compliance workflows.