Biothane

High-performance

Anaerobic

Digestion

Technology for

Industrial

Wastewater

and Sludge

Turn High-COD Waste into Renewable Energy

Industrial sectors such as food processing, breweries, chemicals and pharmaceuticals generate high-COD wastewater that is both energy-rich and challenging to treat through conventional aerobic systems. Increasing sludge disposal costs, higher energy demand and stringent discharge regulations are driving the shift toward advanced anaerobic technologies.

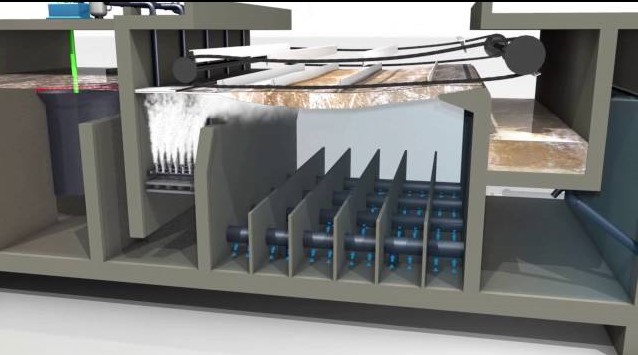

Biothane, developed in collaboration with Livprotec and delivered by WOG Technologies Limited, is a high-performance anaerobic digestion platform designed to maximize biogas recovery and reduce sludge volumes. Its energy-efficient configuration enables industries to convert wastewater into a circular, energy-positive resource while ensuring compliance and lowering operational costs.

Key Features of Biothane

Our process utilizes granular anaerobic biomass with high microbial density for faster start-up and greater stability under variable loads.

WOG’s tailored microbial formulations enhance hydrolysis, acidogenesis and methanogenesis—key stages in achieving stable, high-yield digestion even with complex wastewater.

Available in UASB, EGSB and hybrid configurations to suit varying COD loads, solids content and space constraints.

Designed to handle temperature fluctuations and shock loads without compromising gas output or effluent quality.

Couples seamlessly with biogas engines, CBG bottling units and thermal recovery systems to offset operational energy demand.

What Biothane Delivers?

- Efficient anaerobic digestion of sewage sludge and high-strength industrial effluents, achieving up to 85–90% COD and BOD degradation depending on feedstock.

- High methane yield of 0.35–0.45 m³ CH₄/kg COD removed from compact, low-footprint systems.

- Energy-neutral to energy-positive wastewater treatment, generating up to 70% of plant energy demand through biogas recovery.

- Reduction in sludge generation by 50–60%, significantly lowering hauling and disposal costs.

- Support for biogas-to-power generation and compressed biogas (CBG) output, with potential energy outputs of 3–5 MW from large-scale installations.

Biothane enables industries to meet discharge regulations, reduce OPEX and transition toward anaerobic digestion wastewater energy models that align with circular economy goals.

Where Biothane Works Best?

- Distilleries and Breweries

- Dairy, Starch and Food Processing Units

- Pharmaceutical and Chemical Plants

- Textile and Pulp & Paper Industries

- Municipal Sludge Treatment Plants

Whether your plant handles sludge, high-COD effluent or organic process waste, Biothane offers a proven, scalable pathway to renewable energy recovery and regulatory compliance.

Why Choose Biothane by WOG?

- Over two decades of anaerobic process expertise

- Custom microbial packages for each waste profile

- Designed for rapid ROI and biogas monetization

- Backed by our O&M, automation and environmental compliance teams

- Proven performance across more than 100 industrial sites globally

- Developed in strategic collaboration with Livprotec, leveraging their proprietary anaerobic technology for enhanced biogas recovery and process stability

Biothane is more than a reactor; it is your engine for anaerobic wastewater energy transformation.

Ready to Turn Your Waste into Energy?

Explore how Biothane can deliver anaerobic wastewater treatment that pays back in power, compliance and sustainability.

Contact WOG Technologies Limited today to request a pilot, consultation or commercial proposal.

FAQs

Biothane is ideal for high-COD, low TSS wastewater from sectors such as food processing, pharmaceutical, starch, brewing and chemicals. Biothane is also effective in the anaerobic digestion of sewage sludge and organic-rich effluents.

Granulated sludge contains dense microbial aggregates that settle quickly and retain high microbial activity. This improves gas yield and stability compared to conventional flocculent sludge, especially during load fluctuations.

Depending on COD load and plant size, Biothane systems can generate between 0.35 to 0.5 Nm³ of biogas per kg COD removed, enabling significant on-site power or heat recovery and biogas electricity generation.

Yes. Our modular units and anaerobic hybrid reactor designs make retrofits and upgrades possible with minimal site disruption. Integration with existing aerobic or tertiary units is seamless.

Yes. We offer ongoing biological support, including microbial inoculants, nutrient balance monitoring and troubleshooting to keep your digester performing at peak levels.